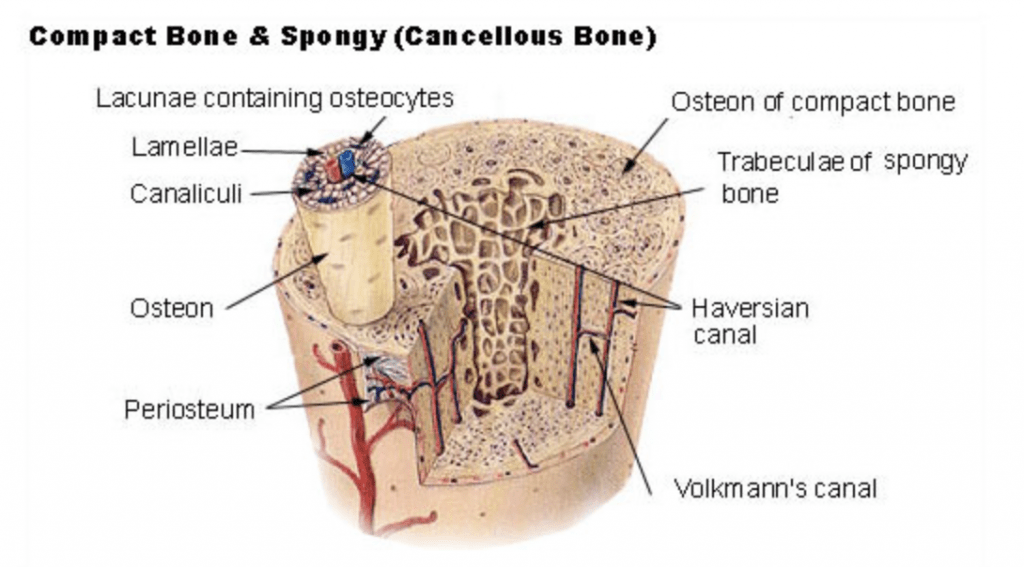

Our lab is especially interested in the spongy region, also known as trabecular bone.

Hi! My name is Amritha, and I’m a rising senior majoring in Biochemistry/Biophysics and Biomedical Engineering through the Dual Degree Program. This summer, I am working in the Bone Bioengineering Lab (BBL) at Columbia University through the Amgen Program, under Dr. Edward Guo.

Healthy bones provide structural integrity and support. Cartilage is the special gel-like matrix that lubricates joints, allowing for low friction and fluid motion between bones. Unlike cartilage, bones remodel themselves every few years. This adaptive remodeling consists of resorption, or bone removal, and repair, which involves filling in resorbed or damaged parts of the bone.

Like most biological processes, the resorption and repair of bone must be balanced. Tipping the scale is believed to be one of the major causes of musculoskeletal disorders. One such disorder is osteoarthritis, which is the most common type of arthritis. It involves degeneration of cartilage and bone tissues at the joint, commonly occuring at the hips, knees, and hands. Osteoporosis is another example of a disorder that results in bone degeneration, and it is responsible for about two million fractures in the United States.

The goal of the BBL is to examine the microstructural and mechanical changes that occur during the bone remodeling process, and better understand how these changes relate to musculoskeletal disease formation using mouse models. The lab uses techniques such as Computed Tomography (CT) scanning, histological analysis, and mechanical properties testing to better understand the complex relationships between growth, repair, and destruction. A CT scanner is kind of like a rotating x-ray machine that is able to reconstruct a 3D representation or image of the object. Histological analysis is microscopic tissue analysis, and an example is paraffin fixation. This involves setting tissue samples in wax, and cutting this into thin slices for analysis under a microscope. The two main types of mechanical properties testing used in the BBL are indentation testing (which analyzes a material’s resistance to dent formation) and tensile testing (which looks into how the stretch of a material varies as the material is exposed to larger loads).

While I’m not in the lab, I enjoy settling down with a good book, painting nature scenes, and connecting with family and friends. As I’ll be in New York for the summer, I also hope to do some sight seeing and other touristy things in my free time. Through ASN, I hope to document my learning experience and the challenges I encounter along the way, while making my research easier to understand for a general audience. See you in the next post!

You must be logged in to post a comment.